CAD-CAM and Milled Crowns

Discussing dental technology is something dentists often enjoy. There have been many technological advancements in our field focusing on improving the patient’s experience while also easing the process for the dentist. Along those lines, you may have come across “single-day crowns” offered by some dentists. This is a relatively newer technology that allows dentists to take a digital impression and send that impression over to an in-office milling machine that fabricates your crown as you wait. I have had the opportunity to work with this technology and would like to take a moment to discuss its pros and cons.

Digital scanners – the devices that Cascadia and many other modern dental offices offer – are used to take digital impressions. Before digital scanners, when a patient had a crown or bridge completed, we would use a material that was loaded onto a tray to capture a negative image or impression of the work we wanted to replicate outside of the mouth. Today we use a handpiece that works to take a 3D image to save that same work digitally.

The biggest player in the game of “single-day crowns” is Sirona, a company that makes a unit known as CEREC. One of the biggest differences with CEREC is that they offer an in-office milling unit that some dentists are utilizing to fabricate crowns in office in “one visit”. The obvious benefit of a one-stop dental visit speaks for itself – the idea that you would only need to come in and get numb once and leave fully satisfied with a brand new tooth is certainly compelling.

The biggest problem with a single-day crown is its limitations for the types of material available to dentists. Although a separate milling unit for a harder material known as bruxir is available, most dentists choose not to invest in a second, far pricier, milling unit and glazing oven. What I typically see from single-day crowns is a type of material called emax or lithium disilicate. Although this is a great material, it makes for a very poor material choice for use on posterior teeth (molars and premolars). In my experience, I have seen these crowns fracture frequently and it’s my recommendation that patients avoid this material on posterior teeth.

It has also been my experience that the visits required to complete a single-day crown are excessively long, which can be arduous for the patient and may also result in a rushed final product. Unlike a dental lab focused on producing thousands of a crowns a month, a single dentist may produce up to a couple a day (at most). Dental labs tend to produce great work and they do it quickly and efficiently but even they can run into issues. In instances where something is not perfect, such as the color, shape or glaze, the production process needs to be started over again and this can be very time consuming and rushed when the dentist is under a time crunch.

It is my opinion that the benefits of digital dentistry are significant and I employ them daily. However, the downsides of then trying to produce crowns, in office, in a single visit, is not something that I see as maximizing the quality of care for my patients. If you would like more information about this topic contact our office at 360-629-7229

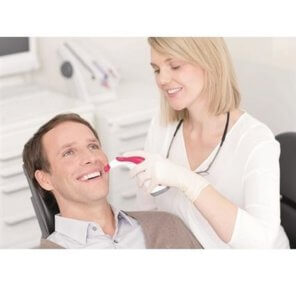

As with everything, technology in dentistry is always improving and changing. As a result, we are always striving to find the best technology to improve the quality and outcome of your dental experience. Along these lines, I am pleased to announce our latest investment: introducing the Vita Easyshade V. The Vita Easyshade V is a tool for taking “custom” teeth shades at the chair without having to rely solely on our eyes. This is important because the slightest difference in tooth shades can really stand out, especially in the front or the “esthetic zone”. Relying on our eyes, alone, is not always sufficient and having another tool in our arsenal for some of the more difficult shade matches is meant to take some of the guess work out of the process. This tool has a great track record, already, and is known as the best digital shade detection system on the market. All we have to do is point the Vita Easyshade at a tooth and it will digitally measure the shade of your existing teeth. It’s that easy!

As with everything, technology in dentistry is always improving and changing. As a result, we are always striving to find the best technology to improve the quality and outcome of your dental experience. Along these lines, I am pleased to announce our latest investment: introducing the Vita Easyshade V. The Vita Easyshade V is a tool for taking “custom” teeth shades at the chair without having to rely solely on our eyes. This is important because the slightest difference in tooth shades can really stand out, especially in the front or the “esthetic zone”. Relying on our eyes, alone, is not always sufficient and having another tool in our arsenal for some of the more difficult shade matches is meant to take some of the guess work out of the process. This tool has a great track record, already, and is known as the best digital shade detection system on the market. All we have to do is point the Vita Easyshade at a tooth and it will digitally measure the shade of your existing teeth. It’s that easy!